Serialization is a vital practice in many industries, especially in the pharmaceutical and food sectors, where product safety and supply chain efficiency are critical. The process involves assigning unique identifiers to individual products or items to track and trace them throughout the supply chain. Serialization has numerous benefits, such as enhanced product safety and supply chain efficiency. However, implementing serialization can be costly. In this article, we will explore the high cost of implementing serialization and provide practical solutions for mitigating this challenge.

5 Ways To Lower The Cost of Implementing Serialization & Traceability

1. Leasing of Equipment

One of the most significant costs of implementing serialization is the capital investment required to purchase the necessary equipment. This equipment includes hardware and software components such as printers, scanners, and servers, which can be expensive. Leasing equipment can help reduce the initial capital outlay required to implement serialization. Companies can lease the necessary equipment from third-party providers to comply with regulatory requirements. Leasing equipment can be a practical solution for small- to medium-sized businesses that cannot afford to invest in expensive serialization equipment.

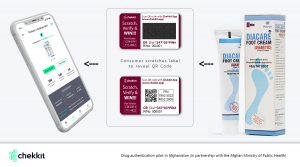

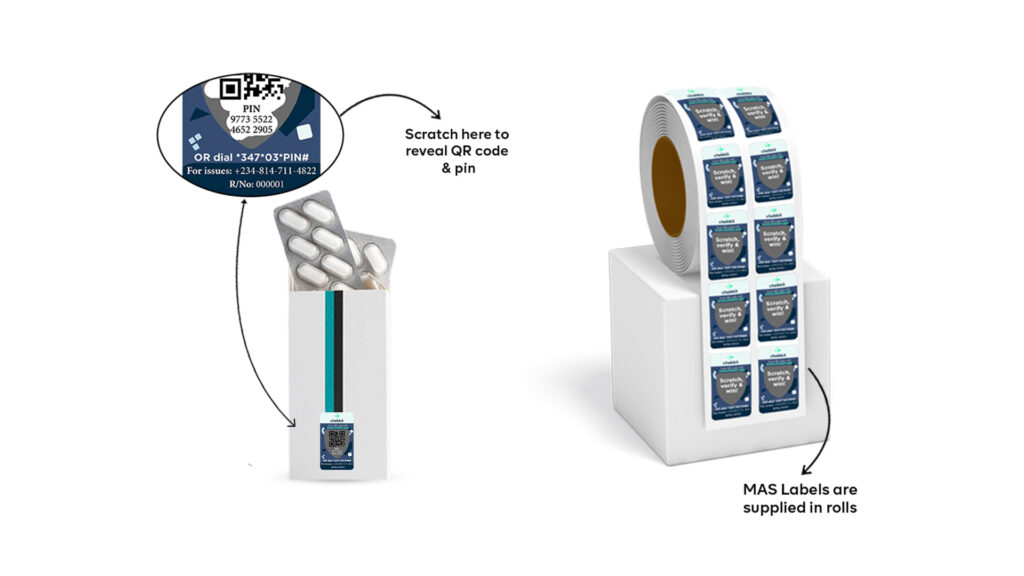

2. Using Sticker Labels

Another cost-effective solution is to use sticker labels to serialize products after production. This approach involves printing unique identifiers such as QR or DataMatrix codes on stickers that are attached to the product packaging. Sticker labeling can be a practical solution for small- to medium-sized businesses that cannot afford to invest in expensive serialization equipment. Sticker labeling can also help companies avoid the high cost of retrofitting existing equipment to meet serialization requirements.

3. Funding from Government Bodies and Other Organizations

Funding from government bodies, NGOs, and other organizations can also help mitigate the cost of implementing serialization. In 2013, the United States Food and Drug Administration (FDA) provided funding to help pharmaceutical companies comply with the Drug Supply Chain Security Act (DSCSA). Such funding programs can be critical for small- to medium-sized businesses that lack the financial resources to invest in serialization equipment. Companies can also explore funding opportunities from local or regional government bodies or industry associations. Grant funding for traceability is popular in the food/agriculture industry and can also be extended to pharmaceuticals.

Funding can also be provided by global NGOs with a stake in the pharmaceutical supply chain.

4. Implementing Serialization in Phases

Implementing serialization in phases can help reduce the cost of implementation. Instead of implementing serialization across all product lines at once, companies can start with a pilot program and gradually scale up serialization as needed. This approach can help companies identify and address implementation challenges in a cost-effective manner. Implementing serialization in phases also allows companies to measure the return on investment (ROI) and evaluate the benefits of serialization before investing in additional equipment.

5. Collaborating with Other Manufacturers

Collaborating with other manufacturers to buy serialization equipment in bulk can also help reduce the cost of implementation. By purchasing equipment in bulk, companies can negotiate lower prices and share the cost of equipment maintenance and support. Such collaboration can be particularly beneficial for small- to medium-sized businesses that lack the financial resources to purchase expensive serialization equipment on their own. Collaborating with other manufacturers can also help companies gain access to expertise and knowledge-sharing opportunities.

While implementing serialization can be a costly endeavor, it is an essential practice for industries where product safety and supply chain efficiency are paramount, therefore, it has to be done. Despite the initial investment required, the benefits of serialization far outweigh the costs. By tracking and tracing individual products throughout the supply chain, companies can enhance product safety and minimize the risks of counterfeit products.

Moreover, serialization can improve supply chain efficiency by reducing inventory errors and facilitating recall management. Companies that take a strategic approach to serialization implementation can realize these benefits and gain a competitive advantage in their respective markets.

If you’re interested in knowing how our pharma serialization and traceability software for manufacturing works, we will be more than happy to walk you through our technology.

As a pharmaceutical manufacturer, this technology will help you stay ahead of the curve and ensure that you can spot new market opportunities long before the competition.